Environment

For environment and human being's respect

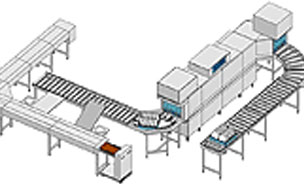

ECO-WASH logo distinguishes all Lamber's products with reduced environmental impact, for a considerable reduction of energy use and an operating costs saving.

For us the environment's respect is more than an engagement. It means being deeply conscious and totally sensible about the environmental matters during every phase of the industrial cycle, from the design to the production. As a further evidence of our traditional concern for environment issues and commitment, we are certified CE-UL-NSF-BELGAQUA-GHOST-ENERGY STAR and ISO 9001.

Respect for environment is a key issue for our company.

In 2011, we installed a photovoltaic plant with a production capacity of 200.000 kWh a year. Considering that for each kWh of energy produced from traditional energy sources, CO2 emissions in the atmosphere are of 0,48 kg, thanks to this new eco-friendly production CO2 atmosphere emissions are reduced to 96.000 kg/year. Not only the new ECO-WASH devices guarantee an electricity consumption reduction up to 50% ( L305-CV, - F840-CV - Heat Pump CVCP) but are also highly biocompatible. The product and firm's certifications guarantee our traditional engagement. The less water and detergent's consumption in the different washing phases, the SRS and WATER PURIFIER systems and the lesser and lesser energy consumption efficiency being equal, make Lamber products more and more convenient for operating costs and quality of the done service. Bigger noiselessness and lesser heat emissions. Technical and technological solutions which mean also a better liveability of your working environment.